La fábrica

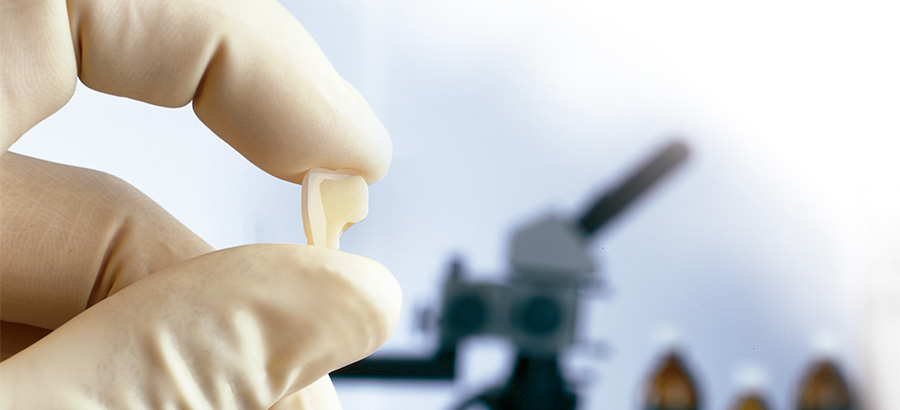

Homogeneidad, pieza por piezaPreparación de resinas

Siguiendo unos estrictos protocolos de calidad, se crean y se pigmentan las resinas que posteriormente serán la materia prima con la que se crearán las

capas, estas capas se combinan en capas, dando a cada una de las piezas dentales el color especificado en la guía de colores.

El aspecto natural y la permanencia de la coloración han hecho a Unidesa-odi famosa en todo el mundo.

Polimerización automatizada de capas

Una vez que los moldes están preparados y colocados en la bandejas, se introducen en la cadena de producción automática patentada por Unión Dental con el nombre de SICM. Este proceso de moldeo le permite a unidesa-odi permite inyectar las resinas correspondientes en cada una de las capas en un momento específico para que se polimericen bajo la presión y temperatura adecuadas.

La dureza y resistencia a la abrasión de los productos de Unidesa-Odi se forjan aquí

Pigmentos minerales es lo que dan a nuestros productos estos colores inalterables al paso de los años.

Los protocolos estrictos garantizan que la combinación de diferentes resinas en capas le da a cada pieza dental su color correspondiente.

Clasificación y Embalaje

Con la piezas ya polimerizadas se llevan a la sala donde se clasifican y ensamblan sobre las tablillas.

En el proceso de clasificación con un sistema de visión artificial no solo se clasifican las piezas sino que se descartan cualquiera que por diversos motivos pueda no cumplir los estándares de calidad que hemos definido.

Por último antes de pasar a preparación de pedidos estas piezas son montadas sobre tablillas y son revisadas otra vez más con el fin que le llegue al cliente este producto que genera confianza en todo el mundo.